Resonac Starts Development of New Semiconductor Materials for 6G at the Newly Opened Innovation Base

— With Computational Science and Materials Analysis Professionals Also Stationed at the Same Resonac R&D Center —

In January 2023, Resonac Corporation (TOKYO: 4004) (President and CEO: Hidehito Takahashi) is launching a project to develop new semiconductor materials for 6G, the next-generation telecommunication system standard following 5G. Resonac will implement this development project, which starts with the molecular design stage, in cooperation with ventures and universities at its “Stage for Co-creation” R&D center newly opened in Yokohama City, where teams of experts, including those in computational science and materials analysis, have been stationed since the end of December. Companies around the world are competing for the development of 6G systems, which are expected to be put into practical use in around 2030. Resonac aims to develop materials that will support high-frequency data transmission in the terahertz band.

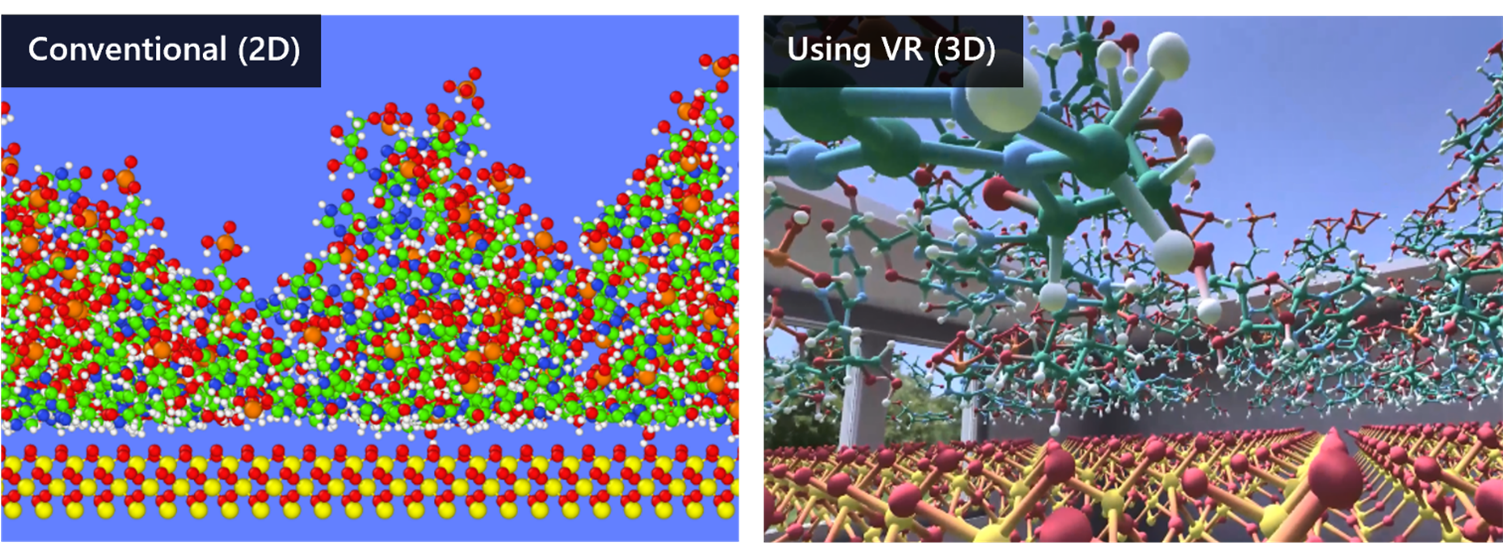

With 6G set to be 100 times faster than 5G, new semiconductor materials are needed to substantially reduce the transmission loss associated with the increased communication speed. To meet this requirement, Resonac will develop materials and technologies for composite materials from scratch, starting with the synthesis of materials to create resins and ceramics for filler materials, as well as developing interface control technologies. In order to identify the optimal combination of materials to provide the required characteristics, Resonac will perform simulations and use AI systems in the molecular design stage to swiftly derive the required chemical structural formulas, a feat that would be impossible using conventional methods. Also, while it would take three months to manually test one combination of materials, the use of AI and other systems will make it possible to test one combination per day, or as many as 90 different combinations in three months.

Such development activities will be supported by a group of professionals with expertise in fundamental technologies for R&D. As a base for open innovation and Resonac’s R&D center, the “Stage for Co-creation” concentrates experts in computational science, materials analysis, manufacturing process technology & equipment management for mass production, and the management & evaluation of chemical safety. For example, the “Research Center for Computational Science and Informatics” has 70 specialists in simulation, AI and MI. These specialists have engaged in the process of developing catalysts from the molecular design stage in the petrochemicals and basic chemicals fields. Many of them are shifting their focus to the development of semiconductor materials to support the development project. Moreover, experts on mass production technology will also make contributions in the production process examination stage.

At the “Stage for Co-creation”, the solution of social issues on a medium-to long-term basis will be pursued as the driving R&D theme. The first initiatives to be implemented under this theme include plastic chemical recycling as well as the development of semiconductor materials for 6G. Toward the achievement of carbon neutrality by 2050, research is being carried out in order to identify a method to recover raw materials for plastics such as ethylene directly from waste plastics. For this, research personnel need not only to overcome technological challenges but also to listen to advice and opinions from those who contribute to the sorted collection of waste plastics and use recycled products. In this and other projects, personnel at the “Stage for Co-creation” will work toward the solution of social issues by promoting dialogue and co-creation with a wide range of stakeholders, including local governments and consumers.

Stage for Co-creation (Yokohama City)