Overview

Resonac’s adhesive tapes are designed to prevent the leakage of resins attached to the backside of lead frames when map molding quad flat non-leaded (QFN) packages. Attaching on the reverse face of a lead frame, it has achieved no flush burr after molding and high productivity in wire bonding.

Features

- Superior wire bonding properties (including Cu wires) due to high Tg, high thermal stability, and low outgassing.

- Superior performance in preventing resin leakage (burrs, mold flashes) during the molding process.

- Low adhesive residue when peeling off the tape.

- Contributes to enhanced productivity with stable wire bonding properties, burr prevention during molding, and low adhesive residue, especially for small package applications such as mini QFN, DFN, and SON.

- Lineup suitability for Cu clip bonding and other high-temperature processes (300-400℃ reflow, etc.).

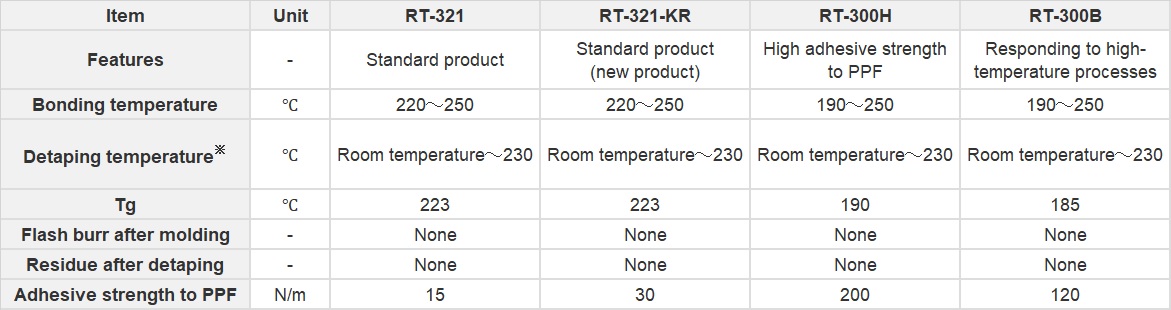

Tape Characteristics & Line-Up

※Heating is required for some lead frames and epoxy molding compounds.

※Heating is required for some lead frames and epoxy molding compounds.